Polymers range from familiar synthetic plastics such as polystyrene to. 841Macroscopic hardness is generally characterized by strong intermolecular bonds but the behavior of solid materials under force is complex.

In the polymeric materials hardness test the most common method is using a Shore durometer hardness test figure 23.

. Polymers are all created by the process of polymerization wherein their constituent elements called monomers are reacted together to form polymer chains ie 3-dimensional networks forming the polymer bonds. Rockwell E Rockwell M Rockwell R generally chosen to test harder plastics PA PC PS Shore A Shore D Hardness Scale often preferred for rubberselastomers and softer. In the flash mix chamber chemicals are added to the water and mixed violently for less than a minute.

Inelastic recovery of the surface makes tests such as Brinell and Knoop tests dicult to assess. The hardness of a material is defined as its ability to withstand localized permanent deformation typically by indentation. In this paper the researchers first focused on a type of polymer structure known as a star polymer network.

Polymer Clay can only be hardened by cooking it in the oven. How to wake up and soften up the plasticizers in your old hard and crumbly Fimo clay blocks. Greek poly- many -mer part is a substance or material consisting of very large molecules or macromolecules composed of many repeating subunits.

The depth or size of resulting indentation is measured and turn to its related hardness number. Lets start with the basics of polymer clay. Polymer synthesized from benzoxazine monomer radiated at 300 kGy.

The type of deformation under consideration when measuring hardness is plastic deformation. In addition the results reveal that the amount of water uptake of polymers obtained from radiated monomer was significantly low whereas the hardness of the polymer synthesized from monomer radiated at 300 kGy was higher than the polymer synthesized from non-radiated monomer. Polymer funny cartoons from CartoonStock directory - the worlds largest on-line collection of cartoons and comics.

The natural polymers are generally monodisperse as all. There is no universal hardness test. Due to their broad spectrum of properties both synthetic and natural polymers play essential and ubiquitous roles in everyday life.

Chris DeArmitt - PhD FRSC CChem. Contact a mineral filler supplier. If the molecules in the mixture have an inconsistent size shape and mass distri-bution the mixture is called polydisperse.

Hardness is a measure of how resistant solid matter is to various kinds of permanent shape change when a force is applied Fig. For rubbers elastomers softer plastics Shore Hardness is often preferred. Therefore drawn fiber usually possesses superior and often preferable mechanical attributes in comparison to simple extruded monofilament.

67 are not suitable for polymers. Aminoplast amino resin K-17-2 FKP-1 polymethylmethacrylate plexiglas polyvinyl chloride. The hardness of the following materials was investigated.

A specimen of at least 14 inch 635 mm thickness is indented by a hard steel ball and the depth of indentation is measured. The result is sometimes shown as a hardness number with an indentation time because the depth of indentations often changes over time due. 70 is an.

Depending on the kind and brand of Polymer Clay the temperature at which the clay has to be baked can range from 210 F to 300 F for up to 30 minutes. Its a very complex area. Specific hardness tests were developed and correlated with the materials.

The hardness measurement has wide applications in the characterisation of the mechanical and physical properties of materials. By using this site you accept our use of cookies as. A polymer ˈ p ɒ l ɪ m ər.

The more in-depth answer is obviously way longer than the answer above. Consequently durometer testing p. Answer 1 of 4.

Strength andor amount of heat treatment metals. Plastic Additives Webinars. Calcium carbonate talc mica wollastonite silica barium sulfate etc.

The Rockwell hardness is usually chosen for harder plastics. One of the most common methods of determining coating hardness is the pencil hardness test also known as the Wolff-Wilborn method where a pencil of a known. Stretching or drawing down of the extruded monofilament is a process Fig.

The dispersity measures heterogeneity of sizes of molecules or particles in the mix-ture. Why do you want to know. This method is frequently used for metals polymers ceramics and coatings 1It has been used to relate hardness with certain physical and mechanical properties of materials.

It is generally used for hard materials like PA PC PS or POM where the resilience or creep of the polymer is less likely to affect results. The type of polymerization mechanism used depends on the type of functional groups attached to the reactants. The mixture is called monodisperse if the molecules have the same size shape or mass.

Then in the flocculation basin the water is gently stirred for 30 to 45 minutes to give the chemicals time to act and to promote floc formation. A polymer can be a 3-dimensional 3D network Imagine of a repeating unit joined together left and right back and front up and down or it is a 2-dimensional 2D network Imagine of the repeating units linked together right left down and up in a sheet or a 1-dimensional 1D. Therefore there are different measurements of hardness.

The hardness of a polymer sample is determined by the penetration of the Durometer indenter foot into the sample. There is no underlying theory for how they work. The depth of penetration as measured in a Rockwell test will be time dependent because of stress relaxation.

Up to 10 cash back Hardness was measured on a Rockwell type instrument modified to measure the depth of the unrecovered indentation. Scratch hardness indentation hardness and. Many of the hardness tests described in Section 26 on p.

And cushioning and resilie. Rockwell Hardness test is one possible method to measure the Hardness of Plastics. In the most general of terms Shore provides the various shore hardness scales ie A B C D DO etc.

Hardness is defined as a materials resistance to permanent indentation. Identification minerals and ceramics. Anything with higher hardness than the PU which means just about anything.

These methods aim to give a relative ranking of the hardness of two materials. CartoonStock uses cookies to provide you with a great user experience. This material has two different.

These coagulants consist of primary coagulants andor coagulant aids. Instant Downloads Inexpensive. The indentors were balls of various diameters and cones with various vertex angles.

Hardness may also be used to describe a materials resistance to deformation due to other actions such as. The overall effect of the draw-down process is increased polymer chain density and strength. The simplest way to understand the term polymer is a beneficial chemical made of many repeating units.

Two scales are frequently used.

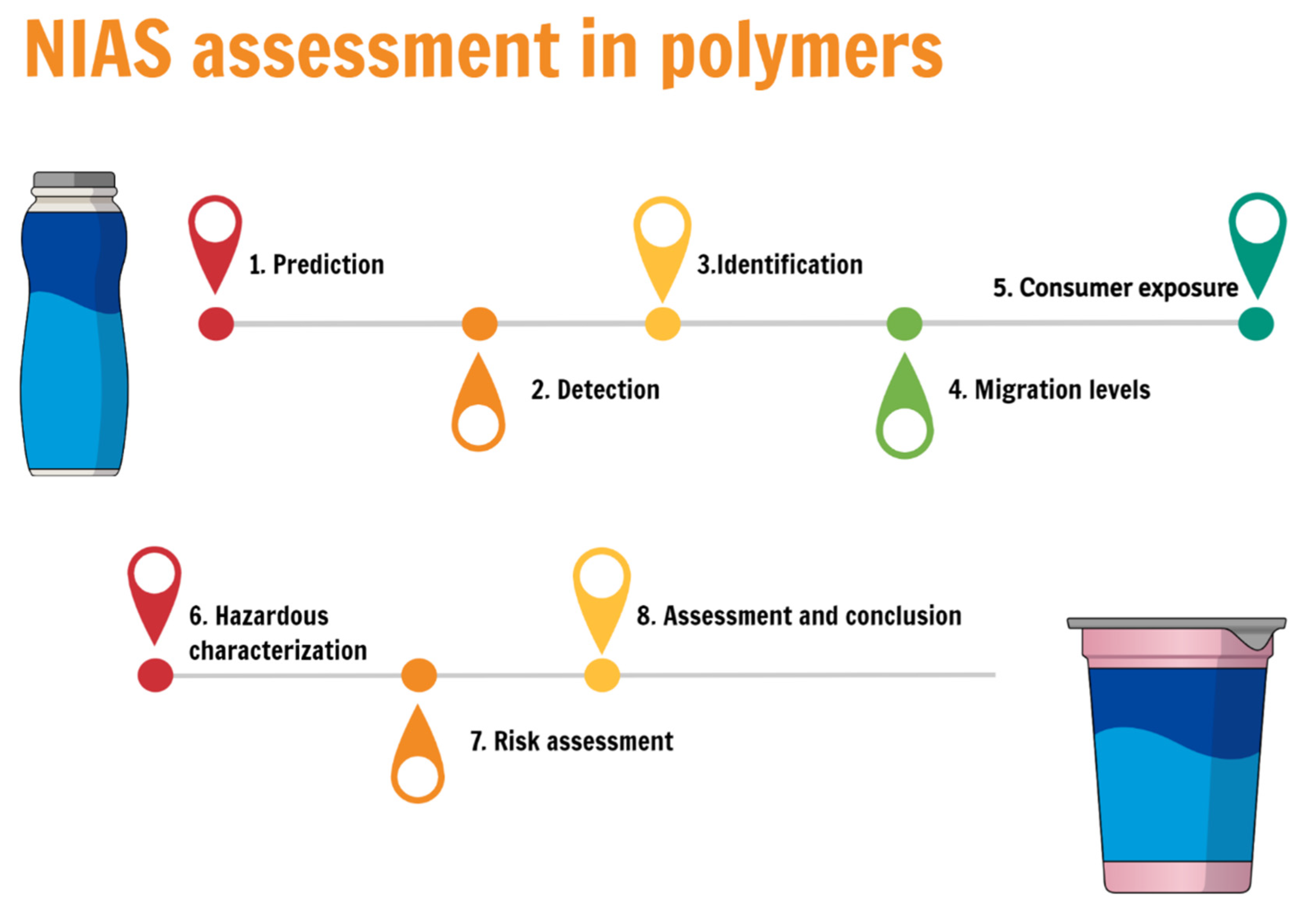

Polymers Free Full Text Safety Of Plastic Food Packaging The Challenges About Non Intentionally Added Substances Nias Discovery Identification And Risk Assessment Html

Cartoon Representation Of Physical Crosslinking Induced By Mixing With Download Scientific Diagram

Personalized Graduation Mug Teacher Thanks You Gift Box Etsy Thank You Teacher Gifts Mugs Teacher Thank You

0 Comments